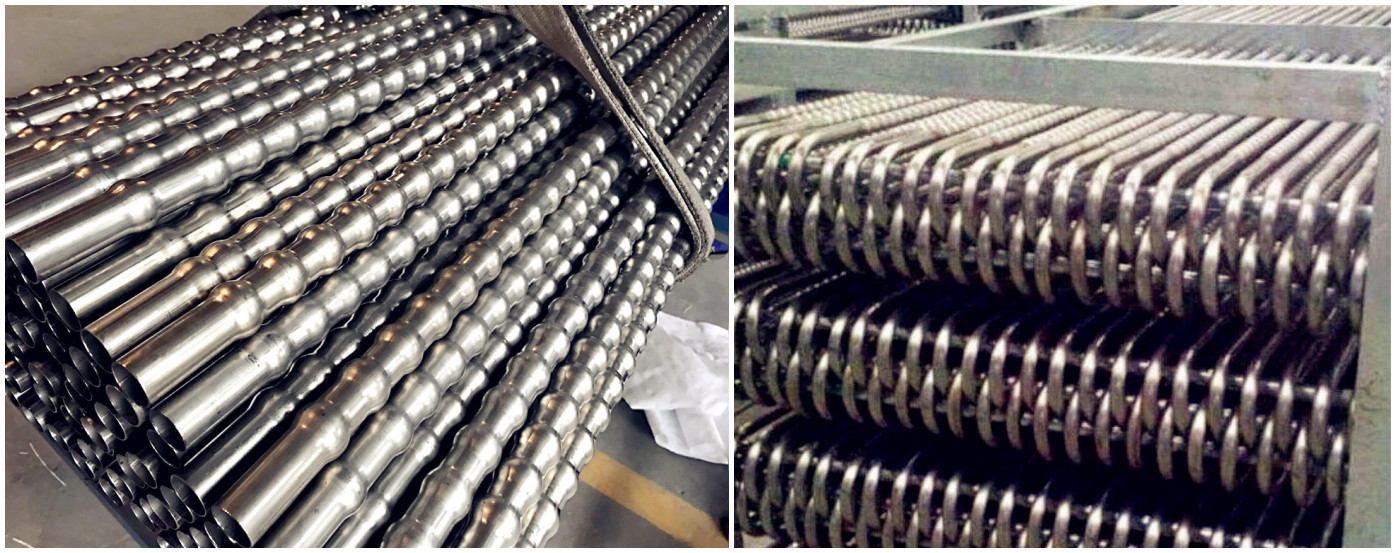

Stainless steel corrugated heat exchanger tube Stainless steelTP304, TP304L, TP321, TP316, TP316L corrugated heat exchanger tube Stainless steel corrugated heat exchanger tube is a new type of high efficiency heat exchanger tube, which repl

Stainless steel corrugated heat exchanger tube

Stainless steel corrugated heat exchanger tube

Stainless steel TP304, TP304L, TP321, TP316, TP316L corrugated heat exchanger tube

Stainless steel corrugated heat exchanger tube is a new type of high efficiency heat exchanger tube, which replaces straight tube. It has the advantages of strong corrosion resistance, longer service life, no pitting corrosion, low price and so on.

We are a professional supplier of boiler tubes and heat exchanger tubes. The corrugated heat exchanger tubes made of stainless steel are our main products.

Our stainless steel wave-knot heat exchanger tubes are made of straight bare-wall tubes by spinning. They are simple in structure, mature in manufacturing technology, easy to scale on the surface and high in heat transfer efficiency. Especially, the axial displacement caused by the change of medium temperature can be compensated by itself during operation. They are widely used in heat exchangers.

Standards:

GB13296-2007 Standard Specification for Seamless Stainless Steel Tubes for Boilers and Heat Exchangers,

ASME SA213 Standard Specification for Seamless Ferrite and Austenitic Alloy Steel Tubes for Boilers, Superheaters and Heat Exchangers

ASTM A269 Standard Specification for Seamless and Welded Austenitic Stainless Steel Tubing for General Service

Material or Grade

TP304, TP304L, TP321, TP316, TP316L, TP310S, TP347H, TP2205, TP2507, TP904L, etc.

Stainless steel corrugated heat exchanger tube Quick Details

Grade: TP304, TP304L, TP321, TP316, TP316L, TP310S, TP347H, TP2205, TP2507, TP904L, etc.

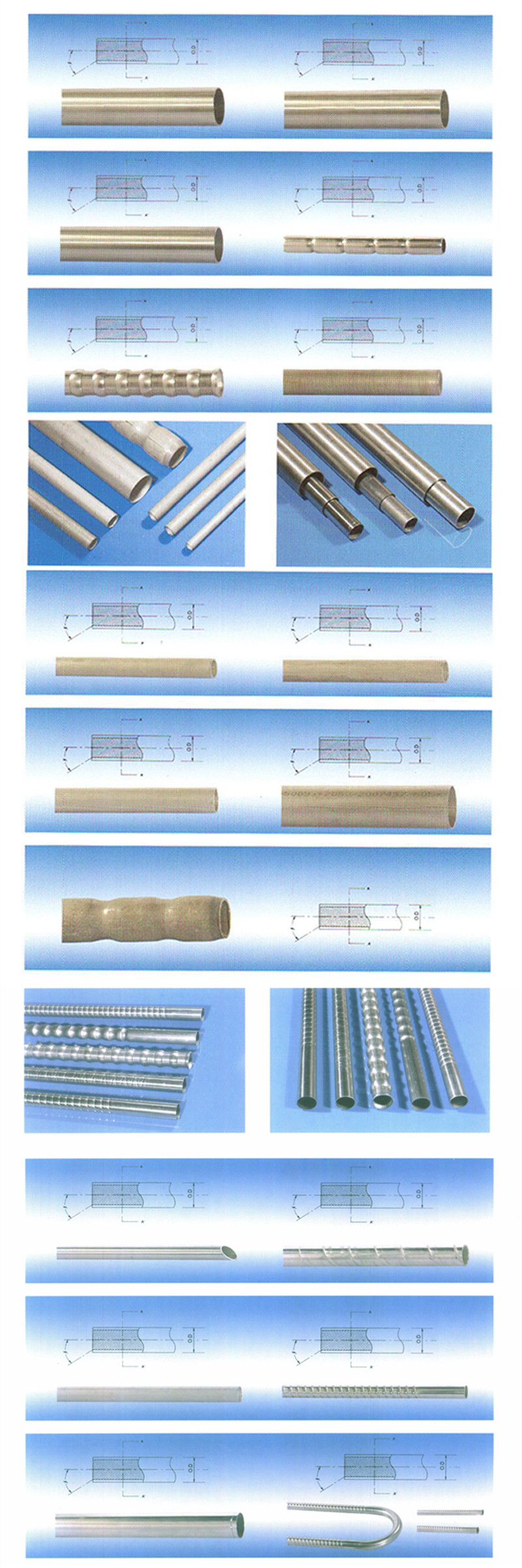

Outside Diameter: 19.0mm-50.0mm

Wall thickness: 0.8mm-3.0mm

Length: 6000mm, 12000m or specified length as required.

Type of End-Finish: Plain End, Treaded

Surface treatment: Tubes will be varnished (Outside only) to prevent rust.

Additional Info

Payment Terms: T/T, LC

Port of Shipment: Tianjin, China

Package: According to To Per Customers'Require

Delivery time: Tubes will be completed within 15 days, and urgent delivery time can be discussed.

Process dimensions:

Conventional diameter of 19 mm, 25 mm, 32 mm, 38 mm are available in stock, according to the requirements of fixed length, the longest can be done 30 m.

According to different applications, cold-drawing (annealing and pickling as soft industrial tubes) and cold rolling (uniform wall thickness, hard state without annealing and bright inside and outside, annealing as soft industrial tubes) can be used.

Chemical composition of Stainless steel corrugated heat exchanger tube

| Grade | C MAX | THE MAX | MN MAX | P MAX | S MAX | NI | CR | MO | OTHER PEOPLE |

| TP 304 | 0:08 | 0.75 | 2 | 0:04 | 0:03 | 8-11 | 18-20 | ||

| TP 304L | 0035 | 0.75 | 2 | 0:04 | 0:03 | 8-13 | 18-20 | ||

| TP 316 | 0:08 | 0.75 | 2 | 0:04 | 0:03 | 10-14 | 16-18 | 2-3 | |

| TP 316L | 0035 | 0.75 | 2 | 0:04 | 0:03 | 10-15 | 16-18 | 2-3 |

Mechanical properties of Stainless steel corrugated heat exchanger tube

| Grade | TENSILE STRENGTH MPA, (MIN) | YIELD STRENGTH MPA, (MIN) | % AGE EXTENSION IN 50 MM GAUGE LENGTH MIN | HARDNESS (MAX) | |

| BHN | RB | ||||

| TP 304 | 585 | 244 | 56 | 191 | 72 |

| TP 304L | 585 | 210 | 56 | 191 | 72 |

| TP 316 | 615 | 245 | 57 | 197 | 75 |

| TP 316L | 585 | 215 | 56 | 197 | 75 |

Tests and Inspection

1. Chemical Composition Analysis Test With 100% PMI and One tube from each heat by Direct Reading Spectrometer

2. Visual Test and Endoscope Test for Surface Quality Test

3. 100% Hydrostatic Test and 100% Eddy Current Test

4. Ultrasonic Test subject to the MPS (Material Purchase Specification)

5. Mechanical Tests includes Tension Test, Flattening Test, Flaring Test, Hardness Test

6. Impact Test subject to Standard request

7. Grain Size Test and Intergranular Corrosion Test

8. Ultrasoic measuring of Wall Thickness

9. 100% Eddy current test after corrugation.

10. Visual test and dimensional inspection after corrugation.

Advantages of stainless steel corrugated heat exchanger tubes

1.High heat transfer coefficient of stainless steel corrugated heat exchanger tube

2.Stainless steel corrugated heat exchanger tube can withstand high temperature, large temperature difference and pressure difference.

3.Stainless steel corrugated heat exchanger tube has strong anti-fouling and anti-fouling functions

4.Stainless steel corrugated heat exchanger tubes have uniform stress distribution and strong corrosion resistance.

5.Long service life and reasonable price of stainless steel corrugated heat exchanger tube

Product key description, this is a very good product description, detailing our product use, product characteristics